Introduction to Malteurop Malting Co.

Malteurop is a group of craftsmen devoted to making exceptional malt. We are innovators, believers in the hard work that goes into true craft, and we pride ourselves on taking the time to do it right.

Our focus in North America is on supplying the highest quality, most exceptional malt products to our brewing, distilling, and food producing partners. That’s right, we call them partners, not customers, because to us, the sale is just a small transaction in a much larger relationship we work hard to cultivate with a hands-on personalized approach to business.

As seriously as our brewers take their craft, we take ours. Leveraging our longstanding history of operating in some of the most fertile barley-growing regions across Europe, combined with our deep-rooted farming heritage, we have an unique perspective and expertise on both the growing and malting process. Our North American products are grown on the continent’s most fertile farmland and crafted by our expert maltsters. Our portfolio includes base, specialty and distilling malts to serve the diverse needs of craft brewers, distillers, and food producers. And through our Barley Breeding Program we collaborate with both craft brewers and growers to develop the next new varietals.

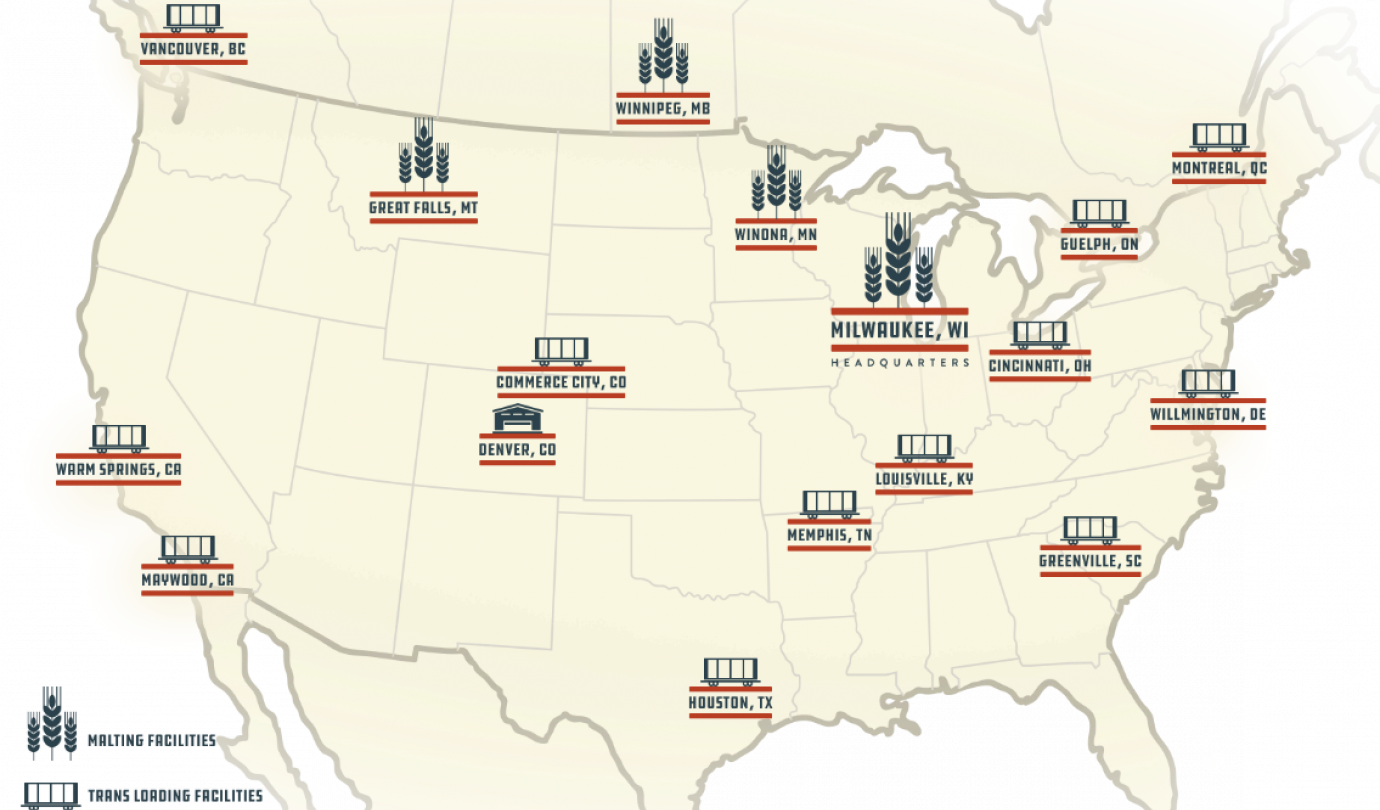

We operate four Malthouses across North America, with distribution centers and transload locations, allowing us to meet, anticipate and adapt to the evolving needs of our brewers, distillers, and food producers, ensuring we deliver on quality, consistency and performance, day in and day out.

As the world’s leading malt producer, we benefit from our sizeable and international reach which yields valuable insights, information and analysis tools for managing high-level agricultural risks while staying on top of market trends to maximize costs and efficiencies for our customers here in the US.

At the core of everything we do, we remain focused on delivering exceptional products to our partners who work as hard and care as deeply for their craft as we do ours.

Learn more about our commitment to craft at MalteuropMaltingCo.com

North American Services

Barley Breeding – Breeding Quality from the Seed Up

We grow the barley. We malt the barley. We even create new barley varieties to meet the changing needs of our craft customers. In fact, Malteurop is the only commercial maltster that has its own barley breeding program. The result? Agronomics that bring better returns to our growers. Barleys that process in the most sustainable ways in our malthouses. And malts that deliver exceptional performance from barley grown in North America.

Malteurop’s program was one of the first to use Doubled Haploid crossing. This technique produces a new generation that is immediately genetically stable. This means fewer years from the lab bench to the farm bin to the brewery. Our first North American variety, Expedition, has been used by leaders in the craft industry since its registration in 2015. They love its European characteristics that shine through even when planted in a very different North American climate. These same brewers look forward to getting their hands on each new generation of unique varieties that come from this one-of-a-kind program

Supply Chain

Malteurop has four Malthouses distributed across North America, as well as distribution centers and transload locations. We supply malts by rail car, 55 lb bags, and everything in between. So our customers know they can rely on us, day in and day out, for the proven quality ingredients they need.

Sustainability

Sustainability is at the heart of Malteurop’s efforts in the Malthouse. Our sustainable water practices—giving preference to non-irrigated barley, reducing water consumption during malting, and ensuring quality of water after malting—are just one example. Investments are also made into smart energy systems and recyclable materials for malt bags, all in an effort to improve our sustainability model.

Corporate Social Responsibility

Malteurop is committed to its community and supports programs each year to give back.

- Shop with a Cop – Malteurop sponsors an annual activity around the winter holidays that brings joy to local children in the Milwaukee neighborhood near the Malthouse. Malteurop provides funding for the local West Milwaukee police force to take local kids out to purchase presents for their family.

- Hunger Taskforce – Each year Malteurop donates food to the local food pantry and supplements the food donation with a financial donation. In 2018, Malteurop sponsored a local charity “Beer Run” that benefitted the Hunger Taskforce. Local Milwaukee employees participated in the run as a way to support the effort.

Markets

Malteurop is committed to servicing customers that are Brewers, Distillers, and Food Producers.

Malting Process

The process of making barley malt consists in 4 stages: steeping, germination, kilning and deculming.

Steeping: the grain is prepared for malting and moistened. Its humidity level then goes from 15 to 45%. The steeping is carried out by immersion or by spraying water, alternating with periods of aeration. At the end of the steeping, the germ and the roots appear, called rootlets. This stage usually lasts between 30 and 45 hours.

Germination: the grain is spread on a perforated tray and continuously ventilated by thermo-regulated air. The germ develops, leading to important biochemical changes in the heart of the grain. This step can last from 3.5 to 6 days. At the end, the plumule reaches the size of the grain and the rootlets that have developed appear faded: we speak then of “green malt”.

Kilning: the green malt is transformed into malt. Thanks to heating and drying, the molecules causing bad taste are eliminated and the aromatic compounds developed. All the art of kilning lies in choosing the right "recipe". After final cooling, the malt leaves the kiln with a moisture content of 4 to 4.5%. Kilning may take up to 2 days.

Deculming: Rootlets that formed during germination are removed using vibrating trays. The grain being very dry, the rootlets are easily detached. At the end of the malting, the malt is in the form of a yellow gold grain dry and brittle. It can be kept for more than one year if strict conditions of storage and hygiene are respected.

Safety

Safety Day

Safety Day is held at all four North American Malthouses in September. Safety Day is a day to engage in education on best practices to avoid injury and also a time to celebrate the progress toward a safer work environment.

Safety Onsite at the Malthouses

The Great Falls Malthouse recently celebrated 2,200 days without a lost time injury.

The Milwaukee Malthouse recently installed a vacuum lifter on the craft malt bagging line to assist the team in moving the 55 lb bag from the bagging line to the pallet.

Safety Beyond Workplace

Regard for safety is a frequent topic and extends beyond the workplace to discussions of how to bring safety into daily awareness and positive habits.

Our Products

Base malts

Specialty malts

More news

Malteurop Malting Company

6737 W. Washington St

Suite 4204

Milwaukee, WI 53214

General Inquiries: 414-671-1166

https://www.facebook.com/malteuropmalting/

https://www.instagram.com/malteuropmaltingco/

https://twitter.com/Malteuropmalt