The production of barley around the world

Barley is a so-called secondary grain, mainly cultivated in Europe, North America, and Australia. It currently represents 7 to 8% of global grain production. The quality of the harvest, the weather conditions, the soil, the species, and the variety all generate diversity. We work with a network of some 10,000 farmers around the world who supply us with high-quality barley throughout the year.

Varieties of malting barley

Winter barley

Winter barley (long growth cycle), specific to Europe, is sown in the autumn to make the most of the low temperatures. Cold is indispensable to the production of seeds through the phenomenon of vernalization.

Spring barley

Spring barley (short growth cycle) is more common around the world; it is sown at the end of the winter. This species grows faster than winter barley, in particular during the first phases of its growth cycle.

Malting

The stages of barley malt production

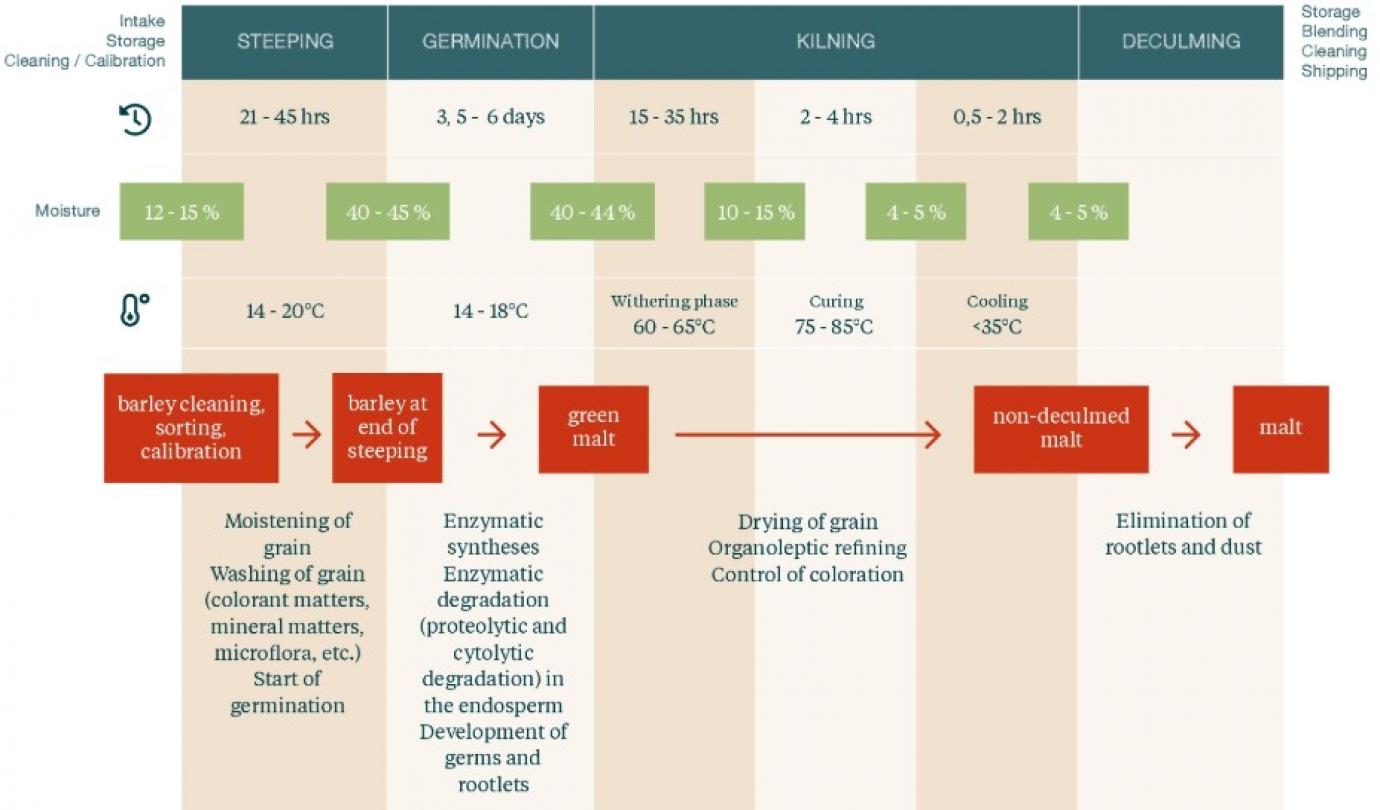

Steeping

Steeping involves wetting the grain to prepare it for malting. Its moisture content increases from 15 to 45%. Steeping is carried out in successive phases where the grain is submerged (underwater) or sprayed, and then oxygenated (air is pumped through the grain). At the end of the steeping phase, the germ and small shoots, called culms, start to appear. This stage generally lasts between 30 and 45 hours.

Germination

During germination, the grain is spread out on a perforated germination bed and continuously ventilated with warm air. The germ develops, causing significant biochemical changes within the grain. This stage can last three and a half to six days. Afterwards, the plumule can reach the size of the grain and the culms appear wilted: we refer to this as green malt.

Kilning

During kilning, the green malt becomes malt. The molecules that generate unpleasant flavors are eliminated by heating and drying, and aromatic compounds develop. The art of kilning resides in choosing the right "recipe". When the malt leaves the kiln, following a final cooling phase, it has a moisture content of about 4 to 4.5%. Kilning can take up to two days.

Deculming

During deculming, the rootlets that developed during germination are removed using vibrating trays. As the grains are very dry, the culms come off very easily. At the end of the malting process, the grain is dry and brittle with a golden yellow color. In the right storage and hygiene conditions, it can be kept for more than a year.

The advantages of barley

The various stages of malt production prepare the starch, which will be turned into sugars, as well as the enzymes, which will be activated during the brewing process because they are necessary for the saccharification of starch. The sugar produced by this process will then be converted into alcohol as the wort is fermented. Barley must have a moderate protein content in order to ensure adequate enzymatic activity while limiting cloudiness in the beer.

The stage of production

Also discover